Applications

MID-IR chemicals sensors have huge potential for innovation in a number of application fields where conventional measurements tools cannot provide in-situ capability, real-time measurement, and unattended operation.

MID-IR chemicals sensors have huge potential for innovation in a number of application fields where conventional measurements tools cannot provide in-situ capability, real-time measurement, and unattended operation.

There is a high demand for efficient and real-time sensors able to monitor industrial process. The chemical industry, oil and gas industry, food and beverage industry, pharmaceutical industry, water treatment and power industries require new technologies to detect the main industrial gases (ex.: CO2, C2H2, C2H4, NO2, N2O, SO2, H2S, CH4 …) or for monitoring chemical processes: the efficiency of a combustion process, the presence of hazardous gases, leakages over large petrochemical installations or the trace of specific chemical compounds.

CL technologies provide new opportunities for developing smaller, faster and more accurate systems. The fundamental absorption bands in the Mid-Infrared (between 3 µm and 20 µm) are more powerful than in the near infrared. Recent advances in QCL and ICL lasers have made compact laser sources available in the MIR. Sensors based on these sources are starting to be used for online or on-field analysis. In fact, these sensors can provide very high detection sensitivity as well as real time measurement in different application fields such as:

Definition: activities involved in ensuring a process is predictable, stable and consistently operating at the target level of performance with normal variation.

Indeed, small changes in a process may have a large impact: variations in proportions, temperature, flow, turbulence, and many other factors must be carefully and consistently controlled.

Includes the chemical industry, the oil and gas industry, the food and beverage industry, the pharmaceutical, water treatment and power industry.

Identifying specific chemical compounds is the main issue: finding the right drilling directions or confirming the location and content of future extraction sites.

Concerns essentially the oil & gas industry but also the mining industry.

Keeping all the production assets and facilities as safe as possible and 24/7 operable without any risk: presence of hazardous compounds or deviation of a process.

Monitoring and diagnosis of air quality are essential for providing clean and safe air for breathing. The atmosphere contains different types of pollutants such as CO, CH4, O2, NOx, NH3, O3, VOC, heavy metals and particulate matter. Excessive quantities of pollutants introduced into Earth’s atmosphere may cause diseases, allergies and sometimes death of humans; it may also cause harm to other living organisms such as animals and food crops, and may damage the natural or built environment.

Besides air pollution, global climate change is driven by the accumulation of greenhouse gases (GHG) in the atmosphere: primarily CO2, CH4 and N2O.

Air quality monitoring is essential for local authorities as well as for industries to detect air pollution and reduce the effect of GHGs. Environmental regulations require continuous emission monitoring (CEM) of all industrial facilities emissions: CEM equipment must be able to operate 24 hours a day in harsh environmental conditions.

Water quality is also an important concern for some specific industries, for example: discharge monitoring in waste water to detect petroleum hydrocarbons (TPH) or oil and grease (TOG).

Mid-IR spectroscopy is particularly appropriate for gas detection and analysis. There are two main types of gas environmental application: Continuous Emission Monitoring (CEM) of processes or stacks and Air Quality Monitoring. For CEM, the tracked or measured gases are mainly simple molecules like SO2, NO2, CO2, CO, NH3 … Air quality monitoring systems include several specific applications. Atmospheric monitoring systems are implemented to monitor the environmental impact of large equipment like highways or factories. Greenhouse gas monitoring stations are critical for gathering more reliable data about global warming.

Mid-IR imaging solutions are emerging in biomedical research (in vivo imaging) and clinical diagnostics by taking advantage of the unique molecular fingerprint of cells, tissue and biofluids and providing in real time a rich biochemical “label free” image.

The most important needs related to MIR sensors are related to the monitoring of chronic diseases such as diabetes and cholesterol: being able to detect them the safest way, at the lowest cost and as fast as possible is a key priority for health care organizations.

Mid-IR spectroscopy enables non-invasive analysis providing non-ambiguous and real time detection of multiple and complex molecules.

Blood Analysis: detection of glucose (C6H12O6), hemoglobin (Hb) and oxygen saturation level (SpO2); and secondly other molecules as a mean to detect infections (anemia, hemorrhage, infection, abnormal glucose rate, abnormal oxygen saturation rate…).

Breath Analysis: detection and measurement of exhaled gases like acetone for diabetes detection, methane about the intestinal environment, nitric monoxide as an indicator of asthma.

Wearables: for glucose sensing, or CO2 detection as headsets or eyeglasses. Also, for continuous monitoring of various chronic diseases through the skin using an implantable or injectable fluorescent dye.

Hospitals Air Quality Monitoring: Hospital acquired infections (HAI) or nosocomial infections, represent a major threat and an important safety issue for hospitals: automatic and real-time CL-based detection systems provide the necessary air quality monitoring including the continuous leakage detection of hazardous gases (inflammable, anesthetic…).

Others:

Chemical imaging in the field of vibrational spectroscopy is complimentary to digital

histopathology: screening of biopsy tissue via automated recognition of tissue/cell

type and disease state. CL-based imaging systems pave the way for crucial enhancements in the field of proteomics, metabolomics, pre-clinical imaging, and structural biology.

CL technology provides useful methods and tools in Security and Safety such as long distance standoff detection, perimeter fences, highly portable detection of multi chemical compounds, hazmat trace detection…

Mid Infrared technology has the ability to provide spectral signatures at a very high sensitivity and thus to distinguish between different materials.

The Security and Safety market aims to use MIR sensors for the fast detection of very small quantities of compounds like drugs, explosives, chemicals or biohazards.

The needs related to the Security and Safety market that could be fulfilled by MIRPHAB sensors are the following:

• Low cost, multi-compound and turn-key solutions,

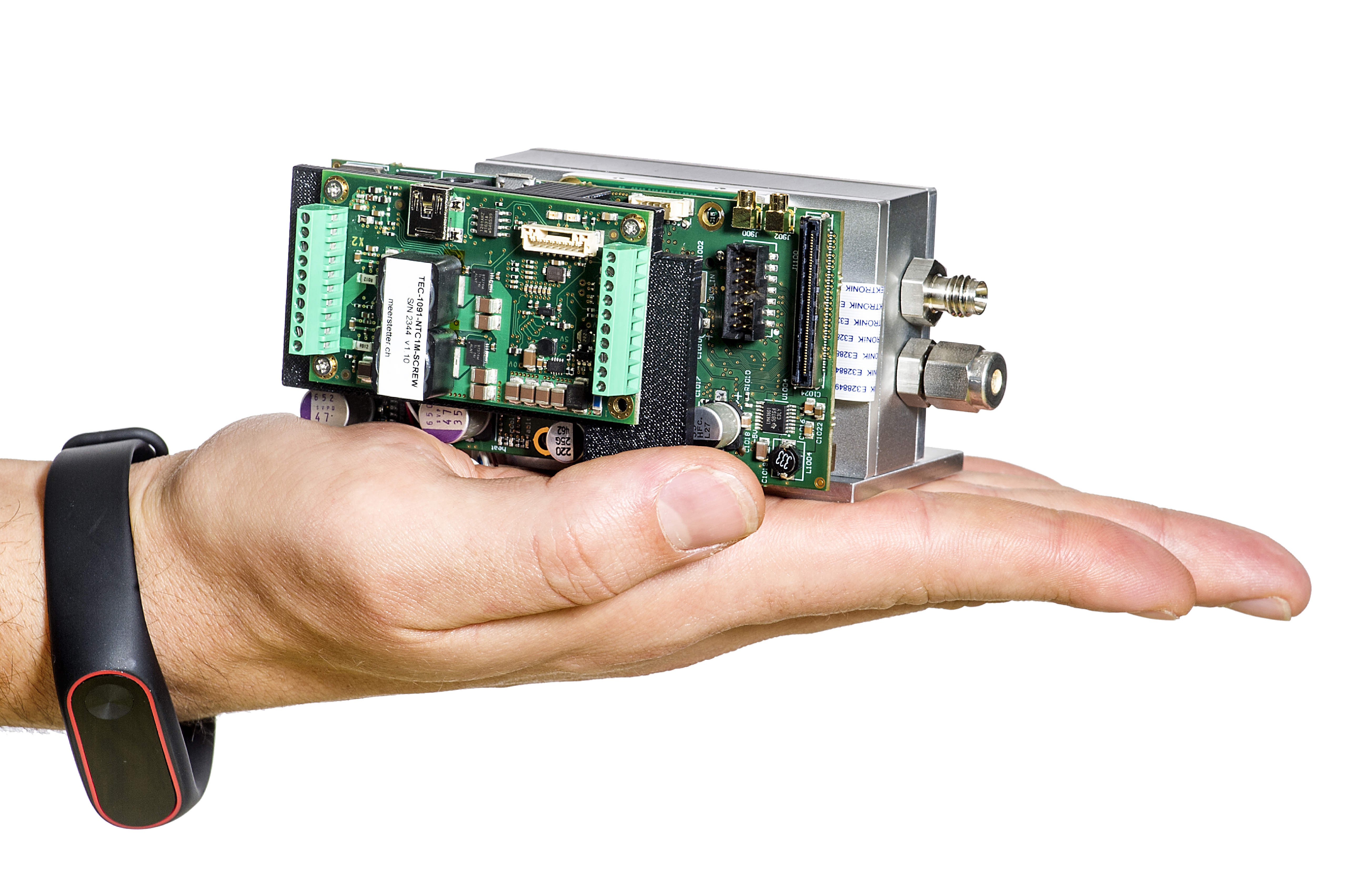

• Ready-to-go subsystems at the source and detector level,

• Compact, mobile and handheld systems.

Today there is a great concern about the concentration of airborne particles and toxic gases, especially around cities. Legislations have been passed in Europe and North America to regulate the concentration of particles and gases in ambient air, and their major targets are the reduction and control of vehicles emissions. Maritime shipping and Air transportation are also highly concerned.

CL based spectroscopy systems can be implemented in various stages of the value chain, for example:

• Control and certification of newly designed engines,

• Vehicle Emissions Monitoring (VEM),

• On-the-road pollution controls.